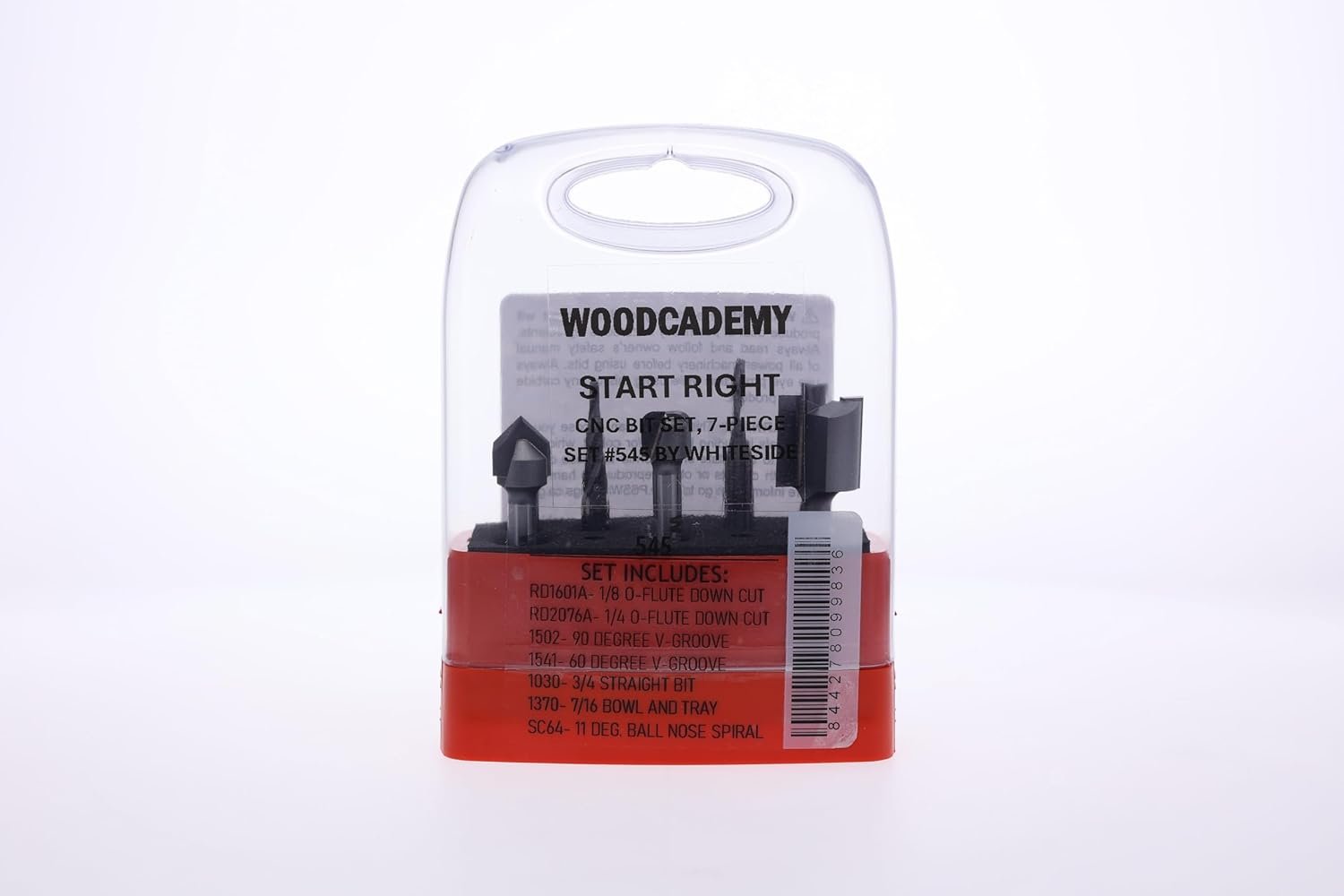

CNC Starter Bit Set from Woodcademy

I am often asked what bits I recommend for a new CNC user just starting out. My choices, based on my decades of experience, are somewhat different from the sets on the market. So I am proud to have teamed up with Whiteside to offer the set I thing will get you started off right.

Made in the USA, these are all 1/4” shank bits to work with any typical CNC, and are all you need to complete all the projects in my new book CNC Woodworking for the Absolute Beginner from Fox Chapel Publishing.

CNC Football Coasters

You can make these fun coasters on your CNC for your next football party. Download the free files for the football shape and follow along with the video.

Gluing up the blank and locating the origin point are the keys to getting great results, but along the way I will share a couple of unusual bits that will save you steps after the milling it done. (Tools used in this video may have been provided to me free by the manufacturers for use in my content).

Free Football Coaster Download Files

Woodpecker Tools Juice Groove Bit

Infinity Tools 3/16” Brass Pilot Bit

Woodworker’s Journal Football Tray Content

Some links above may be affiliate links. Using them helps keep Woodcademy free at no cost to you.

CNC Christmas Ornament for 2024

Our gift to you this year are the files for making this 2024 ornament. I show using a laser to engrave the date, but you can also simply carve the text with a Vee bit.

Easy to make and you can make a bunch to give out for the holidays.

Uses a 5-1/2” by 5-1/2” piece of 1/4” plywood. A .dxf and VCarve files are included, but be sure to verify all the tools and tool paths to match your machine setup.

MicroJig’s CNC Workholding Kit seen on my machines in the video

Links may be affiliate links. Using them helps to keep Woodcademy free at no cost to you.

CNC Piggy Bank

This fun CNC project is easy to make and will appeal to any kid, especially if it comes with some change already inside!

The video explains the process and there is a free download that includes depths of the cuts and the .dxf files needed.

I used the MicroJig CNC Workholding kit for the edge clamping and top-down clamping during the program runs, and one single 1/4” bit for the whole job.

These are affiliate links that help keep Woodcademy Free while costing you nothing to use them.

Feeds, Speeds and Burning, Oh My

Your CNC gives you the control to set the RPM and Feed rate (Speeds and Feeds) for the most efficient cutting. Raising the Feed, lowering the RPM or both reduces friction and greatly extends the life of your bits.

This is one of a series of videos on getting the most from your CNC router bits. You can learn more in my Beginner’s Guide to CNC Machining in Wood from Fox Chapel Publishing.

Router Bits are Not Drill Bits

Routers spin bits too fast to use them for drilling holes. They are just going to overheat and burn. A smaller bit in a pocket toolpath can make the hole needed with better chip clearance and far less friction heating. And this allows for a range of hole sizes all made with one bit rather than changing tools.

This is part of a series of videos with progrmaming tips to get the most from your CNC bits. You can find much more like this in my Beginner’s Guide to CNC Machining in Wood from Fox Chapel Publishing.

Ramping Cuts Prevents Burning

Plunging router bits straight into the stock causesfriction that can burn and damage your bits. Using a ramp command on your CNC makes it easy to get greater tool life from your expensive carbide bits.

This is one of a series of videos using programming tips to extend bit life and prevent burning.

You can find more tips like these in my Beginner’s Guide to CNC Machining in Wood, from Fox Chapel Publishing.

Better CNC Results with Setup Blocks

We all know that plywood thicknesses can vary widely, and this makes it difficult to be sure of cutting through your stock without cutting too deep into your spoilboard. You can measure the stock in hand and adjust the program, but there is a better way.

In this video I show you how to avoid the hassle by setting the Z-Axis off of setup blocks instead of the stock to allow for cutting through a range of size variations while cutting into the spoilboard little if at all.

Veritas Setup Blocks as seen in the video

Whiteside Setup Blocks available on Amazon

Links may be affiliate links that help keep Woodcademy free when you use them and cost you nothing.

CNC / Laser Ornament 2023

I made a bunch of these ornaments for Christmas this year, but the techniques are valuable for a wide range of decorative items you may want to make.

I used a new 1/16” diameter bit. These tiny bits allow for very fine detail cuts and yet are surprisingly resilient. I have yet to break one. I have used both the Freud and the SPE Tools bits, and both work really well.

I sized the ornaments to be decorated with my small laser, but they can be printed, painted or decorated in any number of ways. Use the button on the right to get our newsletter and be among the first to know about great free content like this.

Free dxf file with 2 ornaments

Affiliate Links. Using these helps support Woodcademy at no cost to you.

CNC K-D Tray with Laser Marking

Using a laser to your CNC adds a whole new dimension of abilities. The laser is the perfect addition for marking and decorating parts before milling them.

See how Ralph does it on this clever snap together Serving Tray.

Curious About Amana's In-Groove System?

I have been curious about this system for some time now, so I finally broke down and bought one to try out. Watch to see what I found out!

ShopBot Long Z- Axis Touch Plate

A short video showing the advantage to having the long Z-axis touch plate that comes with a ShopBot.

Sometimes you need to zero tools over or along the edge of an open pocket. The long touch plate spans the gaps to provide an accurate position.

Design and Make Gnocchi Boards on Your CNC

These gnocchi board files are perfect for you to practice adapting CAD programs to customize your projects.

You can download a free folder with several dxf files, pick the one you like best and then follow along with the video to adapt it and personalize it for your own use.

Gnocchi Board DXF File Download

Find loads more CNC training in my book, Beginner’s Guide to CNC Machining in Wood, from Fox Chapel Publishing.

Make Templates With Your CNC

Making templates and patterns for shop projects is something I do a lot in my shop.

My CNC makes these templates quickly and accurately. This video will show you many advantages to this process.

You can learn how to get the most from your CNC with my book; “Beginner’s Guide to CNC Machining in Wood” from Fox Chapel Publishing.

The CNC shown is the ShopBot Desktop 2418.

A Quick Tip for the Best Edge Cuts

Tools and machines both flex a little under load. This is why you can generally see (and need to sand out) the lines for each pass when cutting through.

There is a simple toolpath option you can use to eliminate these tool marks, and in this video, Ralph shows it to you.

You can learn more techniques like this working through the projects in “Beginner’s Guide to CNC Machining in Wood”.

A Tale of 3 Bits: Up, Down and Straight

I get a lot of questions about the difference between Up Spiral, Down Spiral and Straight router bits.

So, I set up a test running them side by side in a blank made of three different materials.

See how they compare head to head.

And learn more about how to choose and use the best bits on your machine in my book.

CNC Charcuterie Set

Learn how using the right bits can round over the parts being cut on your CNC.

See how the “onion skin” technique holds parts without tabs that need to be cut and sanded after.

Watch how you can cut the parts free and finish the edges in one step after milling.

Recently, I helped Woodworker’s Journal with a fun pig shaped charcuterie board project for the CNC. You can find the video and downloadable files here.

I liked the board so well that I decided it needed some “piglet” plates to make it a set, and milled them using my ShopBot Desktop CNC.

Download the DXF file and the VCarve Program.

Cut and Finish CNC Parts in One Step

I often use an “onion skin” technique, leaving a thin layer of material behind to hold parts rather than using tabs. This generally provides a smooth edge that does not need as much cleanup as tabs, but does require the parts to be flush trimmed out of the leftover web.

Trimming the parts using a 1/4” bit inside a 1/4” slot can be tricky, and then the bottom edge usually needs to be eased or chamfered as a secondary operation.

But Infinity Tools Brass Pilot Trim bit set features a 3/16” diameter pilot on the bits so it passes easily through the cut slot and the bits come in a variety of round over and even chamfer sizes. So I can cut the parts free from the stock AND finish the lower edge all in one pass using a trim router. All I need is a 1/4" access hole to start the cut.

Infinity Tools sent me the set free of charge for this video.

See the Brass Pilot Router Bits Here.

I cover tabs, onion skins and many other programming topics in my book; Beginner’s Guide to CNC Machining in Wood Check it out.

Halloween Candy Dish on your CNC

This project is fun to make and can teach you a lot about bit choices and proper programming to get the best results. The same techniques I teach throughout my book: “Beginner’s Guide to CNC Machining in Wood”.

The ShopBot Desktop CNC in the video is on loan to me from ShopBot Tools.

Affiliate links to bits:

Freud Dish Carving Bit #19-104

CNC Carved Tissue Box Cover

This nice cover is sized to go over a standard rectangular tissue box. I used textures on the bottom of the panels, but they have enough space for lettering, logos or image carvings.

There is a free download to go with the video that includes notes and the .dxf file for the box top, sides and ends.